Component 3 focuses on strengthening the role of industry and the private sector in reducing plastic pollution and advancing Bangladesh’s transition toward a circular economy. Recognizing that sustainable plastics use requires a systemic shift across production, design, and disposal, this component engages actors throughout the plastics value chain—including manufacturers, retailers, recyclers, and healthcare providers.

The project initiated its efforts with a national industry mapping exercise, identifying key players and assessing their current practices, challenges, and opportunities related to plastic use. Through targeted dialogues with business chambers, associations, and private sector leaders, the project promoted a shift in perception, framing sustainability not as a compliance burden but as a competitive advantage in increasingly circular global markets.

Resource Efficient and Cleaner Production (RECP) emerged as a central pillar of the component. Selected plastic-intensive industries underwent RECP assessments, receiving tailored recommendations to reduce plastic use, improve energy and water efficiency, and minimize overall waste generation.

These assessments led to the adoption of cleaner technologies, packaging innovations, and the substitution of virgin plastics with recycled or biodegradable alternatives. This work was supported by capacity-building sessions and technical assistance, ensuring that factories had the tools and knowledge to implement improvements.

In parallel, the project addressed the urgent issue of biomedical plastic waste, particularly in response to the dramatic increase in hazardous waste during and after the COVID-19 pandemic. A pilot biomedical waste management model was launched in Sirajganj District, covering all healthcare facilities across nine upazilas. The initiative, led by the District Medical Waste Management Committee (DMWMC) and supported by the Department of Environment (DoE), Directorate General of Health Services (DGHS), UNIDO, and local partners, introduced a centralized system for safe segregation, collection, treatment, and disposal of biomedical plastics.

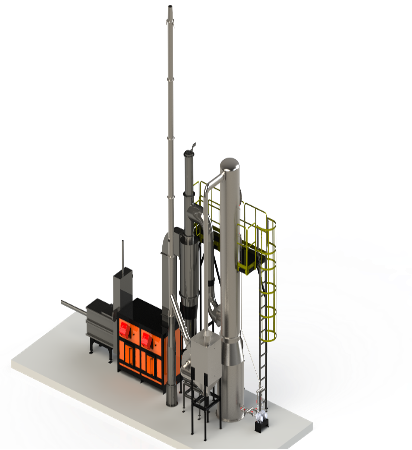

At the core of this model are two advanced treatment technologies, an autoclave and incinerators, supported by the development of a Common Treatment Facility, waste collection infrastructure, and training of 90 healthcare professionals and 20 master trainers.

The initiative is expected to treat over 1,390 tons of hazardous waste and recycle up to 136 tons of biomedical plastics annually, significantly improving public health, reducing environmental pollution, and creating green jobs.

In addition, the project has facilitated market linkages between recyclers and producers, promoted the use of non-virgin plastics, and supported retailer awareness campaigns. Through exhibitions, technical roundtables, and sustainable design workshops, the private sector has been encouraged to adopt circular solutions at scale.

Together, the RECP and biomedical waste streams under Component 3 represent a comprehensive private sector response to plastic pollution. By embedding sustainability into both industrial production and healthcare systems, the project demonstrates how environmental goals can align with economic resilience and public health.

Upcoming Events

Patharghata Clean-up Event

- 11 Dec, 2025

- Patharghata

- Register Now

Barguna Sadar Clean-up Event

- 10 Dec, 2025

- Barguna Sadar

- Register Now

Pirojpur Cleanup

Every cleanup starts with someone willing to take the first step. By registering as a Community Leader, you’re not just signing up for an event — you’re committing to be part of a growing mov...

- 22 Sep, 2025

- Pirojpur, Bangladesh

- Register Now